Point 1: High refractoriness

With TCaST molds, you can cast various metals from aluminum alloy with a pouring temperature of 700C to cast stainless steel or carbon steel with pouring temperatures of above 1600C.

Point 2: Excellent mold collapsibility

TCaST molds are strong enough before casting, and the strength is lost after metal is poured. This makes the collapsibility better compared to conventional molds.

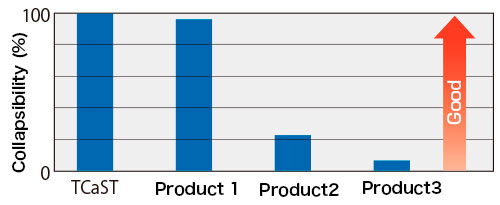

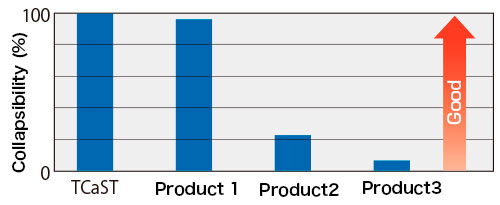

Collapsibility of TCaST and other molds

Impact collapsibility of TCaST heated to 600℃ compared with conventional Taiheiyo products

※Specimen size: 50 mm diameter x 50 mm long

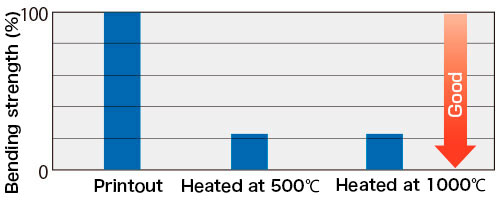

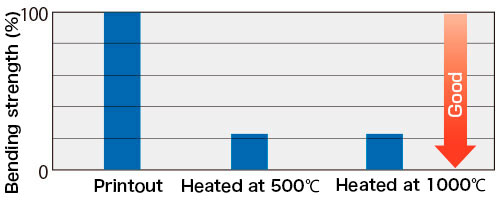

Bending strength of TCaST

Bending strength after heated at different temperatures

※Specimen size: 80 × 16 × 10 mm

Point 3: High precision

Surface precision is very high, so you can get faithful reproduction of smooth curves, fine patterns, embossed letters and logos and other fine designs.TCaST is suitable for crafts as well as for industrial products.

Specifications of TCaST

TCaST overview

- Particle size: 100 μm

- Bulk density: 1.5 g/cm3

- Bending strength: 1 to 5 MPa

- Packing: 10 kg/pack (aluminum bag)

Compatible printers (examples)

ProJet CJP 660

ProJet CJP 660

- Brands and Series

- 3D Systems ProJet x60 Series

- ProJet CJP 160

- Maximum build volume: 236×185×127 mm; Layer thickness: 0.1 mm

- ProJet CJP 660

- Maximum build volume: 254×381×203 mm; Layer thickness: 0.1 mm

- ProJet CJP 860

- Maximum build volume: 508×381×229 mm; Layer thickness: 0.1 mm

Features and Specifications

Features and Specifications

ProJet CJP 660

ProJet CJP 660